At Leadshine, we pride ourselves on delivering high-quality servo drive systems that enhance automation and improve efficiency for our clients. Our EL6 Series AC servo drives are designed to cater to a variety of industrial applications, boasting features that ensure precision and reliability. However, like any technology, issues can arise. This article aims to guide businesses in troubleshooting common problems associated with our servo drive systems.

Recognizing Communication Errors in the Servo Drive System

One of the most frequently encountered issues with servo drive systems involves communication errors. These can disrupt the flow of information between the AC servo drive and the controller, leading to performance degradation. If users notice erratic motion or failure to respond to commands, it is essential to check the connection cables and wiring. Ensure that the Modbus RTU, EtherCAT, or CANopen configurations are correctly set.

Additionally, verifying the settings in the control software can help eliminate potential mismatches affecting communication. A well-documented setup process combined with a thorough understanding of the servo drive system's configuration is vital for efficient operation. If problems persist, consulting the user manual for diagnostic tools and error codes can provide further insights into resolving the issue.

Addressing Motor Matching Challenges

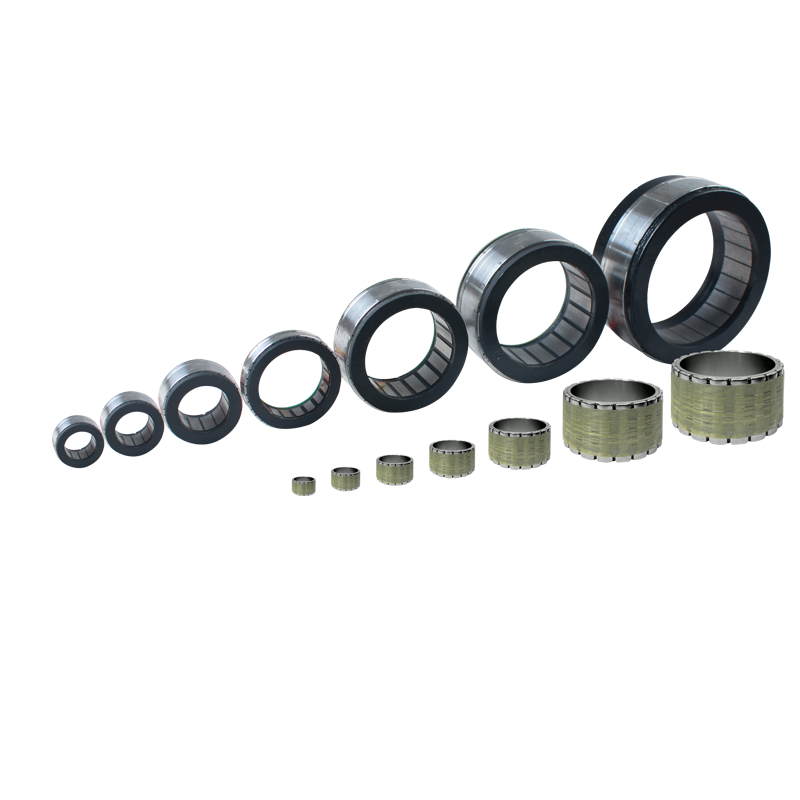

Another common challenge that users face is motor matching difficulties when working with AC servo drives. The EL6 Series features automatic motor recognition; however, certain conditions may lead to compatibility issues. In cases where the motor does not respond or operate erratically, ensure that the motor connections are secure and that the correct motor type has been selected in the servo drive system settings.

Employing 23-bit encoders enhances precision, but if the chosen encoder does not match the drive specifications, users may need to adjust their setups accordingly. Correctly identifying the motor type and ensuring compatibility with our drive system will significantly improve performance and minimize operational disruptions.

Dealing with Performance Fluctuations

Performance fluctuations can occur in any servo drive system, including Leadshine's EL6 Series. Factors such as environmental conditions, load variations, and mechanical wear can affect performance. To troubleshoot this issue, first examine the load being applied to the system. If it exceeds the rated specifications of the AC servo drive, it could cause the system to underperform.

Vibration suppression features included in our servo drives can help mitigate some performance issues. Ensuring the correct tuning of these features is crucial for stable operation. Additionally, routine maintenance checks on components and connections can prevent performance-related problems before they escalate.

Conclusion

In conclusion, while challenges are inevitable when using servo drive systems like Leadshine's EL6 Series, understanding and addressing these common issues can lead to effective resolutions. By carefully examining communication settings, ensuring proper motor matching, and monitoring performance, businesses can harness the full potential of their AC servo drives. At Leadshine, we are committed to supporting our customers in maintaining optimal performance within their automation systems.